YB∕T 4584-2017 莫来石物相分析方法/Phase compositions analysis method of mullite

莫来石 物相分析方法

1 范围

本标准规定了莫来石原料中物相组成及其含量分析方法的原理、设备与试剂、试样制备、试验步骤、结果计算与表示、试验报告等。

本标准适用于莫来石原料中物相组成及其含量的分析。

2 规范性引用文件

下列文件对于本文件的应用是必不可少的。凡是注日期的引用文件,仅注日期的版本适用于本文件。凡是不注日期的引用文件,其最新版本(包括所有的修改单)适用于本文件。

GB/T 6682 分析实验室用水规格和试验方法

GB/T 8170 数值修约规则与极限数值的表示和判定

GB/T 17617 耐火原料与不定形耐火材料 取样

3 原理

在18℃条件下,用20%氢氟酸溶液浸泡3.5h,使刚玉、莫来石与可溶解相分离,然后测定不溶物中刚玉相含量,从而计算出莫来石中各物相的含量。

4 设备与试剂

分析中,除另有说明外,仅使用确认为分析纯的试剂,所用水应满足 GB/T 6682 中二级水的要求。

4.1 制样机。

4.2 标准筛。

4.3 天平,精度 0.0001g。

4.4 恒温水浴槽,控温精度 0.5℃。

4.5 X射线衍射仪。

4.6 硫酸,(5+95)。

4.7 氢氟酸,(1+1)。

5 试样制备

按 GB/T 17617 从产品中抽取实验室样品。将抽取的样品破碎至 3mm后再缩分,制备的综合试样重量应不少于 200g,取其中 100g研磨至 0.096mm(160 目)。

6 试验步骤

6.1 测定次数

独立地进行两次测定,取其平均值。

6.2 试料量

称取约 1g 试样(m,),精确至 0.0001g.

6.3 将称好的试样置于 100mL,塑料烧杯中,以数滴水润湿试样后,慢慢加入氢氟酸(见 4.7)40mL,将其放在恒温水浴槽中,保持温度在 18℃~20℃,浸泡 3.5h,每隔 0.5h 搅动一次。

6.4 用塑料漏斗及慢速滤纸过滤。残渣用硫酸(见 4.6)洗涤8次~9次,再用水洗3次,把不溶残渣连同滤纸放入恒重的铂坩埚中,低温烘干,灰化后,置于 300℃~400℃高温炉中,逐渐升温至 800℃并灼烧30min,取出置于干燥器中,冷却至室温,称重。

6.5 重复灼烧,至恒重(m)。灼烧时,每次灼烧 15min。

6.6 定量取 6.3~6.5 定后的残渣(m;)。

6.7 将残渣试样重复按 6.3~6.6操作至恒重,称重(m)。

7 结果计算与表示

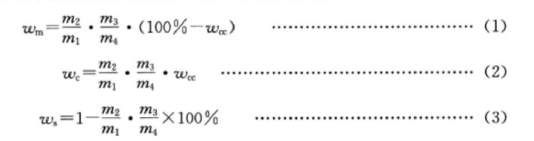

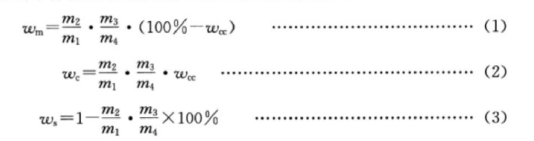

7.1 按式(1)~式(3)计算莫来石原料中各物相的质量百分含量,以质量分数表示:

式中:

wm–试样中莫来石的质量分数,%;

wc–试样中刚玉的质量分数,%;

ws–试样中氢氟酸中可溶解相的质量分数,%;

wcc–氢氟酸溶解,灼烧后残渣中的刚玉相质量分数,%(XRD法实测);

m1–试样质量,单位为克(g);

m2–氢氟酸溶解后、灼烧后试样残渣质量,单位为克(g);

m3–6.6 中所取的试样残渣质量,单位为克(g);

m4–6.7 中所取的试样残渣经氢氟酸再次溶解后的质量,单位为克(g)。

7.2 分析结果按 GB/T 8170 修约,计算结果小数点后保留两位有效数字。如果两次独立分析结果差的绝对俏大于表1所规定的允许差时,则按附录 A的规定追加测量次数并确定分析结果。

8 允许差

允许差见表 1。

|

表1允许差 %(质量分数) |

||

|

莫来石相+刚玉相,可溶解相 |

莫来石相 |

|

|

实验室内 |

1.0 |

1.2 |

9 试验报告

试验报告应包括下列信息:

a)识别样品、实验室和试验日期所需的全部资料;

b)标准编号;

c)结果及其表示;。

d)采用的分析谱线;

e)测定中发现的异常现象;)

f)对结果可能产生影响而在本标准中没有规定的任何操作。

Phase compositions analysis method of mullite

1 Range

This standard specifies the principle, equipment and reagents, sample preparation, test procedures, calculation and expression of results, and test report of phase composition and content analysis methods in mullite raw materials.

This standard is applicable to the analysis of phase composition and content in mullite raw materials.

2 Normative reference documents

The following documents are essential for the application of this document. For dated references, the date-only version applies to this document. For undated references, the latest version (including all amendment orders) applies to this document.

GB/T 6682 Analytical laboratory water specifications and test methods

GB/T 8170 numerical revision rules and limit value representation and judgment

GB/T 17617 Sampling of refractory raw materials and amorphous refractory materials

3 Principles

At 18℃, soak 20% hydrofluoric acid solution for 3.5h to separate corundum and mullite from soluble phase, and then determine the content of corundum phase in insoluble matter, so as to calculate the content of each phase in Mullite.

4 Equipment and reagents

In the analysis, unless otherwise indicated, only reagents confirmed as analytical pure are used, and the water used should meet the requirements of secondary water in GB/T 6682.

4.1 Prototype production.

4.2 Standard sieve.

4.3 Balance, accuracy 0.0001g.

4.4 Constant temperature water bath, temperature control accuracy 0.5℃.

4.5 X-ray diffractometer.

4.6 Sulfuric acid,(5+95).

4.7 Hydrofluoric acid,(1+1).

5 Sample preparation

Laboratory samples were taken from the product at GB/T 17617. The extracted sample will be broken to 3mm and then divided, the weight of the synthesized sample should be not less than 200g, of which 100g is ground to 0.096mm(160 mesh).

6 Test Procedure

6.1 Measurement times

Make two measurements independently and take their average values.

6.2 Test quantity

Weigh approximately 1g sample (m,) accurate to 0.0001g.

6.3 Place the measured sample in a 100mL plastic beaker, wet the sample with a few drops of water, slowly add 40mL hydrofluoric acid (see 4.7), place it in a constant temperature water bath, keep the temperature at 18℃~20℃, soak it for 3.5h, and stir it every 0.5h.

6.4 Filter with plastic funnel and slow filter paper. The residue is washed with sulfuric acid (see 4.6) for 8 ~9 times, and then washed with water for 3 times. The insoluble residue together with filter paper is put into a constant weight platinum crucible, dried at low temperature, after ashing, placed in a high temperature furnace of 300℃~400℃, gradually heated to 800℃ and burned for 30min, taken out in a dryer, cooled to room temperature, weighed.

6.5 Repeat to constant weight (m). When burning, each time burning 15 minutes.

6.6 Residue after 6.3~6.5 determination (m;) .

6.7 The residue sample is repeatedly operated at 6.3~6.6 to constant weight and weighed (m).

7 Result calculation and presentation

7.1 Calculate the mass percentage content of each phase in mullite raw material according to formula (1) to formula (3), which is expressed as the mass fraction:

Formula:

wm— mass fraction of mullite in sample,%;

wc— mass fraction of corundum in sample,%;

ws— mass fraction of soluble phase in hydrofluoric acid in sample,%;

wcc– mass fraction of corundum phase in residue after hydrofluoric acid dissolution,%(measured by XRD);

m1— sample mass, in grams (g);

m2— mass of sample residue after hydrofluoric acid dissolution and burning, in grams (g);

The residue mass of the sample in m3–6.6, expressed in grams (g);

The mass of the residue of the sample taken in m4-6.7 after being redissolved by hydrofluoric acid, expressed in grams (g).

7.2 The analysis result is revised according to GB/T 8170, and two significant digits are reserved after the decimal point of the calculation result. If the absolute difference between the results of the two independent analyses is greater than the allowable difference specified in Table 1, the number of additional measurements shall be added and the analysis results determined in accordance with Appendix A.

8 Allowable error

The allowable differences are shown in Table 1.

|

Table 1 allows differences %(Mass fraction) |

||

|

Mullite phase + corundum phase, soluble phase |

The mullite phase |

|

|

Laboratory |

1.0 |

1.2 |

9 Test Report

The test report shall include the following information:

a) All the information needed to identify the sample, laboratory and test date;

b) Standard number;

c) The results and their representation; .

d) Analytical spectral lines used;

e) Anomalies found in the determination;

f) any operation not specified in this standard that may have an impact on the results.